Green-Tech Design: more than a restyling for the CB family

![]() 2 minutes to read Stefano's point of view about Green-Tech Design

2 minutes to read Stefano's point of view about Green-Tech Design

There are many ways to define the commitment of companies that decide to include the social and environmental dimension in their business. For the Brema Group, corporate social responsibility passes increasingly through the "Be Eco-Active" trend.

This is the Be Eco-Active line launched in 2016 with the introduction of the HC range for the CB family ice machines.

HC, the propane R290 gas, is a natural, colourless, odourless, natural gas with a green heart.

From January 2022, the ice machines of the CB family will take another step forward thanks to the Green-Tech Design approach.

From production to disposal, every aspect takes care about the environmental impact, starting with the materials used and their assembly.

Green-Tech Design is study, design and awareness up to the possibility for end-of-life recycling of all the materials used.

Because, whatever its size and activities, every business is part of an increasingly globalised system that impacts and by which it is impacted. And the resources it uses particularly the natural ones belong to a single planet and we must all strive to safeguard. The great news for the CB family is given the possibility to separate raw materials at the end of their life cycle.

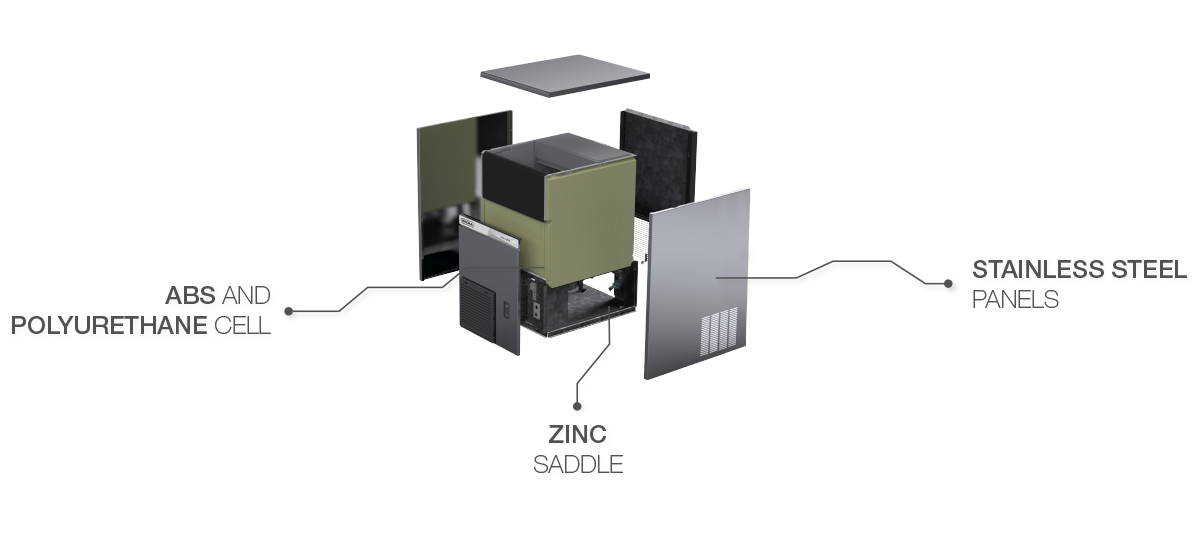

We are not talking of a single cell but three separate blocks which can be recycled separately at the end of their life. In detail, we will have:

With a few simple steps, the engineer can separate the machine into its parts.

For example, he can operate on a vital component such as the compressor or the fan simply by removing the stainless-steel panels, without having to remove the whole unit anymore.

Brema Innovation Center offers you some data to better understand how this evolution of the CB family has less impact on the environment and on society as a whole.

The Innovation Center has also estimated that, thanks to the new conformation, the transportation volume of the parts is reduced by 33 percent, with a consequent reduction of 55 percent of CO2 emissions into the atmosphere.

In the event of accidental damage to the panels or the tank during transport or during normal use of the machine, the Green-Tech Design will allow them to be removed and immediately replaced without having to remove and dispose of the whole unit.

This is a great step forward.

How will the appearance of the Ice Machines change?

We have deliberately sought to not drastically change the classic elegance that has always distinguished the range. But to create a visual difference with the past, we have designed a new ID plate with more modern graphics, to make the type of ice produced much clearer at graphic level. The CB family is available in both the Ice Cube and the B-Qube variants. At a glance this distinction will be immediate.

What are the other benefits, in terms of pluses, of the ice makers produced in a Green-Tech Design key?

The absence of the water-polyurethane in the legs of the machine has allowed us to improve the air circulation through the side apertures that also guarantee a longer life for the machine.

In the water condensate machines, we thought it as a duty to introduce the double water inlet.

Two advantages:

- you can use non potable water or wather from chiller systems in the condensation inlet

- it will be possible to dedicate the other inlet, exclusively, to water destined to become ice, for example by installing a filtering system that guarantees a pure and uncontaminated product.

And more. The power cable has also been designed like the laptops’ one allowing greater connection versatility wherever you are.

UT – Laboratory | Technical | Brema Group S.p.A.